Introduction to Oxygen Regulator

Welcome to our comprehensive guide on how to properly maintain and care for your Oxygen Regulators! Whether you’re a healthcare professional, a home oxygen user, or anyone relying on this vital piece of equipment, ensuring its proper upkeep is crucial for safety and efficiency. In this blog post, we will delve into the essential steps and best practices to keep your oxygen regulator in top condition. Let’s dive in and learn how to make the most out of this critical device that plays a key role in delivering life saving oxygen therapy.

What is an oxygen regulator?

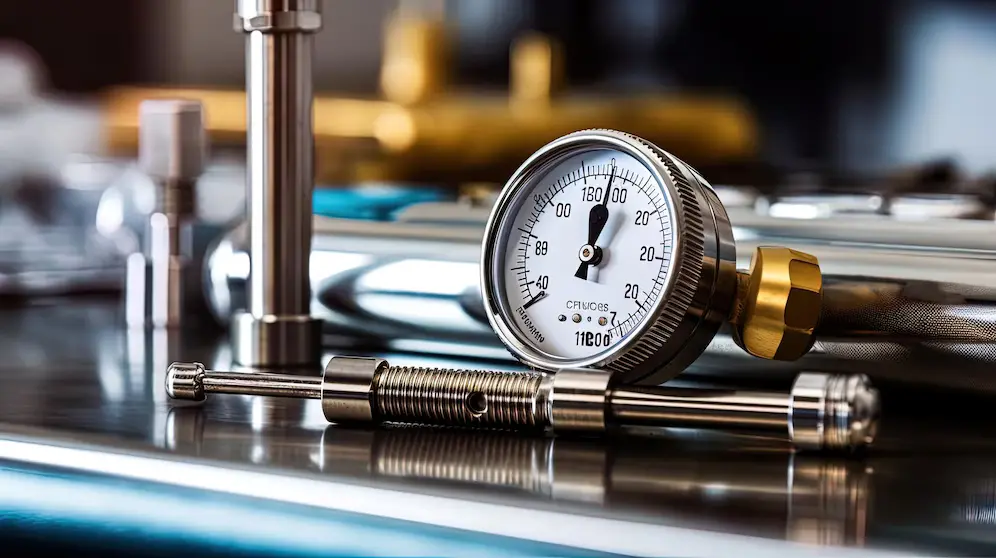

Do you ever wonder how oxygen gets delivered at a precise flow rate for medical purposes? Well, that’s where an oxygen regulator comes into play. This essential device attaches to the top of your oxygen tank and regulates the pressure of the gas coming out.

An oxygen regulator consists of various components such as a pressure gauge, flow meter, and adjusting knob. These parts work together to ensure a steady flow of oxygen based on the prescribed settings by healthcare providers.

The primary function of an oxygen regulator is to control the amount of oxygen being released from the tank. By adjusting the flow rate, patients can receive the necessary level of supplemental oxygen to support their respiratory needs effectively.

Understanding how an oxygen regulator functions is crucial for maintaining its optimal performance and ensuring reliable delivery of oxygen therapy when needed most.

Understanding the Components

When it comes to understanding the components of your oxygen regulator, it’s essential to familiarize yourself with its various parts. The primary components include the pressure gauge, flow meter, and the adjusting knob.

The pressure gauge indicates the amount of oxygen remaining in the cylinder, allowing you to monitor your supply levels effectively. The flow meter controls how much oxygen is being delivered to the patient per minute. It is crucial to adjust this based on individual needs.

The adjusting knob allows you to regulate the flow rate according to prescribed settings. Properly setting this ensures that the patient receives the correct amount of oxygen for their condition. Familiarizing yourself with these components will help ensure proper functionality and efficient use of your oxygen regulator.

Safety Precautions

When it comes to maintaining and caring for your oxygen regulator, safety should always be a top priority.

First and foremost, ensure that the area where you are working with the Oxygen regulator is well ventilated to prevent any buildup of potentially dangerous gases.

Always wear appropriate personal protective equipment such as gloves and eye protection when handling the regulator to protect yourself from any potential hazards.

Make sure to follow all manufacturer guidelines and recommendations regarding the safe operation of the regulator. This includes properly securing it in place and avoiding any rough handling that could damage the components.

Regularly inspect the Oxygen regulator for any signs of wear or damage, and immediately address any issues to prevent them from escalating into safety concerns down the line.

By taking these safety precautions seriously, you can help ensure not only your own well being but also prolong the lifespan of your oxygen regulator for optimal performance.

Regular Inspection

Regular inspection of your regulator is crucial to ensure its proper functioning and safety. Start by visually examining the regulator for any signs of damage, leaks, or wear and tear. Check all connections to make sure they are secure and free from blockages.

Next, test the pressure gauges to verify accurate readings. Inspect the flowmeter for smooth operation and check that the knob turns easily without resistance. Pay attention to any unusual noises or vibrations during operation as these could indicate underlying issues.

It’s important to follow manufacturer guidelines for inspection frequency and procedures. Keep a detailed record of each inspection to track any changes or trends over time. By staying proactive with regular inspections, you can catch potential problems early on and prevent costly repairs or replacements down the line.

Cleaning Procedures

Keeping your oxygen regulator clean is essential to ensure its optimal performance and longevity. Start by gently wiping the exterior of the regulator with a soft cloth dampened in mild soapy water. Avoid using harsh chemicals or abrasive materials that could damage the delicate components.

For more thorough cleaning, remove any detachable parts according to the manufacturer’s instructions. Soak these parts in a solution of warm water and mild detergent, then rinse them thoroughly and allow them to air dry completely before reassembling.

Pay special attention to crevices where dust or debris may accumulate, using a small brush or cotton swab to reach those tight spots. Regular cleaning not only prevents contamination but also helps identify any potential issues early on, ensuring your regulator continues to function safely and efficiently.

Lubrication Techniques

Lubrication plays a crucial role in maintaining the functionality of your oxygen regulator. Proper lubrication techniques can prevent friction and wear within the components, ensuring smooth operation.

When it comes to lubricating your oxygen regulator, always refer to the manufacturer’s guidelines for recommended products and frequency. Using the wrong type of lubricant can damage the regulator and compromise its performance.

Before applying any lubricant, make sure to clean the components thoroughly to remove any dirt or debris that could affect its function. Apply a small amount of approved lubricant sparingly on designated areas as specified by the manufacturer.

Avoid over lubricating as this can attract dust and particles which may clog up sensitive parts of the regulator. Regular maintenance with appropriate lubricants will help extend the lifespan of your regulator and keep it functioning optimally for longer periods.

Calibration Guidelines

Calibration guidelines are crucial in ensuring the accuracy and reliability of your oxygen regulator. Proper calibration helps maintain optimal performance levels, providing you with peace of mind knowing that your equipment is functioning correctly.

When calibrating your regulator, always refer to the manufacturer’s instructions for specific guidance on the process. It’s essential to follow these guidelines meticulously to avoid any errors or inaccuracies in calibration.

Regularly scheduled calibration checks are recommended to ensure that the Oxygen regulator remains within specified tolerances. By adhering to these guidelines, you can detect and address any potential issues promptly before they escalate into more significant problems.

Maintaining accurate calibration not only enhances safety but also contributes to efficient oxygen delivery. Consistent monitoring and adjustment based on established guidelines will help maximize the lifespan and performance of your oxygen regulator.

Storage Practices

When it comes to storage practices for your oxygen regulator, it is crucial to keep the equipment in a safe and clean environment. Store the regulator in a dry area away from direct sunlight or extreme temperatures to prevent any damage.

Make sure that the storage location is well ventilated and free from dust or debris that could potentially clog or contaminate the regulator. Avoid storing the equipment near chemicals or flammable materials to reduce any risk of accidents.

It is advisable to place the oxygen regulator on a stable surface where it won’t be knocked over or damaged accidentally. Consider using a protective cover when storing the regulator for an extended period to shield it from dust and other particles.

Regularly check the storage area for any signs of moisture buildup, leaks, or pests that could compromise the integrity of your oxygen regulator. By following proper storage practices, you can ensure that your equipment remains in optimal condition for when you need it most.

Handling and Transportation

When it comes to handling and transporting your oxygen regulator, there are a few key points to keep in mind. Always ensure that the regulator is securely attached to the oxygen cylinder before moving it. This will prevent any accidental damage or dislodging during transportation.

Be mindful of how you handle the regulator to avoid any unnecessary impacts or rough handling that could compromise its functionality. It’s important to treat the equipment with care and respect to maintain its effectiveness.

Additionally, when transporting your oxygen regulator, make sure it is stored in a clean and dry environment away from extreme temperatures or direct sunlight. This will help preserve the integrity of the materials and prevent any potential damage.

Always use proper lifting techniques when moving the oxygen cylinder with the regulator attached to minimize strain on your body and reduce the risk of accidents. By following these guidelines, you can ensure safe handling and transportation of your oxygen regulator wherever you go.

Troubleshooting Common Issues

Troubleshooting common issues with your oxygen regulator is essential to ensure its optimal performance. One common problem you might encounter is a leaking regulator. If you notice any hissing sounds or feel air escaping, check for loose connections and tighten them as needed.

Another issue could be inconsistent flow of oxygen. This might indicate a blockage in the system or a faulty regulator. Inspect the tubing for any kinks or obstructions and replace if necessary.

If you experience difficulty adjusting the flow rate, the knob or dial on your regulator may be damaged. Try cleaning it first, and if that doesn’t work, consider replacing the part.

In case your regulator shows inaccurate pressure readings, it could be due to a malfunctioning gauge. Regularly calibrating your gauge can help prevent this problem.

Always refer to the manufacturer’s guidelines for specific troubleshooting steps tailored to your model of oxygen regulator.

Oxygen Supply System Maintenance

Maintaining your oxygen supply system is crucial to ensure its optimal performance and reliability. Regularly inspect all components, including hoses, fittings, and connectors for any signs of wear or damage. Clean the system thoroughly to prevent dirt or debris from affecting its functionality.

Proper lubrication techniques are essential to keep the moving parts of the system operating smoothly. Follow manufacturer guidelines for calibration to ensure accurate oxygen delivery. When storing the system, make sure it is in a dry and well ventilated area away from direct sunlight or extreme temperatures.

Handle and transport the system with care to avoid any potential damage. Be prepared for emergencies by having backup supplies readily available in case of unexpected situations. Stay informed about manufacturer recommendations and seek proper training on how to maintain and troubleshoot your oxygen supply system effectively.

Upgrading or replacing outdated components when needed will help prolong the lifespan of your regulator while minimizing downtime due to malfunctions.

Emergency Preparedness

In the world of healthcare, emergencies can happen unexpectedly. Being prepared is key when it comes to maintaining and caring for your oxygen regulator. Having a well thought out emergency plan in place can make all the difference in critical situations.

Ensure that you have easy access to spare parts and tools needed for any potential repairs or replacements during an emergency. It’s also important to have a backup oxygen supply system readily available if your primary regulator malfunctions.

Regularly review and update your emergency preparedness procedures with all relevant stakeholders involved in the care and maintenance of the oxygen regulator. Conduct drills and training sessions to ensure everyone knows their role during an emergency situation.

Stay informed about any regulatory guidelines related to emergency response protocols for oxygen equipment. Compliance with these standards will help you effectively manage emergencies involving your regulator.

Manufacturer Recommendations

When it comes to maintaining your regulator, following the manufacturer’s recommendations is crucial. These guidelines are designed to ensure the optimal performance and longevity of your equipment. Manufacturers often provide detailed instructions on how to properly clean, inspect, and calibrate the regulator.

Additionally, they may offer specific lubrication techniques that are compatible with their product to prevent damage or malfunction. It’s important to adhere to these recommendations to avoid voiding any warranties associated with the device.

Manufacturers also typically outline storage practices that can help protect the regulator from environmental factors such as moisture or extreme temperatures. By following these suggestions, you can prolong the lifespan of your equipment and ensure its reliability in emergency situations.

Always refer back to the manufacturer’s guidelines for any troubleshooting tips or maintenance procedures. Being proactive in adhering to their recommendations will ultimately benefit both you and your oxygen regulator in the long run.

Training and Education

Training and education are crucial aspects of properly maintaining an oxygen regulator. It is essential for individuals who handle these devices to undergo comprehensive training to ensure they understand how to operate, inspect, and troubleshoot the equipment effectively. This knowledge empowers users to identify potential issues early on and take appropriate actions.

Education on the components of an regulator helps users grasp the intricate mechanisms involved in its function. By understanding how each part contributes to the overall operation, individuals can better appreciate the importance of regular maintenance practices. Training also emphasizes safety protocols that must be followed when handling regulators to prevent accidents or malfunctions.

Ongoing education ensures that users stay updated on any advancements or changes in Oxygen regulatory guidelines related to oxygen equipment. Regular refresher courses or workshops can provide valuable insights into new techniques for calibration, storage recommendations, and emergency preparedness strategies. Continuous training cultivates a culture of responsibility and competence among those responsible for the care of oxygen regulators.

Upgrading and Replacement

When it comes to your oxygen regulator, staying up to date with advancements in technology is crucial. Upgrading your regulator can enhance its performance and efficiency, ensuring you receive the highest quality of oxygen therapy.

Consider replacing your regulator if it shows signs of wear and tear or no longer functions optimally. Upgraded models often come with improved safety features and user friendly functionalities that can make a significant difference in your oxygen therapy experience.

Consult with your healthcare provider or equipment supplier to determine the best time to upgrade or replace your Oxygen regulator. They can provide valuable insights on the latest options available that meet your specific needs and requirements.

By investing in upgrading or replacing your Oxygen regulator when necessary, you are prioritizing your health and well being. Stay informed about new developments in oxygen therapy equipment to ensure you have access to the most advanced solutions for managing respiratory conditions effectively.

Environmental Considerations

When it comes to maintaining and caring for your Oxygen regulator, environmental considerations play a crucial role in ensuring its optimal performance. The environment in which the regulator is stored and used can impact its functionality over time.

Factors such as temperature, humidity levels, exposure to chemicals or gases, and dust accumulation can all affect the longevity and efficiency of your regulator. It’s essential to store the regulator in a clean, dry place away from direct sunlight and extreme temperatures.

Regularly inspecting the surrounding area for any potential hazards or contaminants that could compromise the integrity of the regulator is also important. By being mindful of environmental factors and taking proactive measures to mitigate risks, you can help prolong the lifespan of your oxygen regulator.

Impact of environmental factors on the regulator

The environment plays a significant role in the performance and longevity of your oxygen Oxygen regulator. Exposure to extreme temperatures can affect its accuracy and functionality over time. High humidity levels may lead to corrosion of the regulator components, compromising its reliability.

Additionally, exposure to dust, dirt, or other contaminants can clog the Oxygen regulator’s vents and valves, causing it to malfunction. It is essential to store the regulator in a clean and dry environment when not in use to prevent these issues.

When transporting the regulator, ensure it is properly protected from any potential damage due to rough handling or impact during transit. Avoid storing or using the device near sources of heat or direct sunlight as this can also impact its performance.

Regular maintenance checks should include inspecting for any signs of environmental damage and taking preventative measures to ensure optimal functioning of your regulator.

Compliance with Regulations

Compliance with regulations is a crucial aspect of maintaining and caring for your oxygen regulator. It’s essential to adhere to all guidelines set forth by regulatory bodies to ensure the safety and effectiveness of the equipment.

Regulations are put in place to protect both users and those around them, as well as to maintain the integrity of the oxygen supply system. By following these regulations diligently, you can help prevent accidents or malfunctions that may occur due to non compliance.

Make sure to stay up to date on any changes or updates in regulations related to Oxygen regulators. Being informed and proactive will not only keep you safe but also help you avoid any potential legal issues that may arise from non compliance.

Always consult with experts or manufacturers if you have any doubts or questions regarding regulatory compliance. They can provide valuable insights and guidance on how best to meet all necessary standards for proper maintenance and care of your regulator.

User Responsibility

As a user of an oxygen regulator, it is crucial to understand your responsibility in maintaining and caring for this vital piece of equipment. Your role goes beyond just using the device; it involves ensuring its proper function and safety at all times.

One key aspect of user responsibility is following manufacturer guidelines for usage, maintenance, and storage. These instructions are designed to keep you safe and extend the lifespan of the regulator.

Regularly inspecting the regulator for any signs of damage or wear is another important task that falls under your responsibility. By catching issues early on, you can prevent potential malfunctions or accidents from occurring.

Proper handling and transportation practices are also essential parts of user responsibility. Always secure the regulator during transport to avoid any damage that could impact its performance.

Remember, taking ownership of these responsibilities not only ensures your safety but also contributes to the efficiency and reliability of your oxygen supply system overall.

Benefits of Proper Maintenance

Proper maintenance of your oxygen regulator comes with a range of benefits that go beyond just ensuring its functionality. By regularly maintaining and caring for your regulator, you can extend its lifespan and optimize its performance, providing you with peace of mind knowing it’s in top condition when you need it most.

Maintaining your regulator also reduces the risk of unexpected malfunctions or breakdowns, which could be critical in emergency situations where every second counts. Additionally, proper care can help prevent costly repairs or replacements down the line.

Regular maintenance not only keeps your equipment functioning efficiently but also promotes safety by identifying any potential issues early on. This proactive approach minimizes risks associated with using a faulty regulator and ensures a reliable oxygen supply whenever needed.

Incorporating routine maintenance practices into your healthcare routine is essential for maximizing the longevity and effectiveness of your regulator. So, make sure to prioritize proper care to reap these valuable benefits in the long run.

Extending the lifespan of the oxygen regulators

Extending the lifespan of your oxygen regulator is crucial to ensure its optimal performance and safety. Regular maintenance and care play a key role in prolonging the life of this essential medical device.

By adhering to manufacturer recommendations for cleaning, lubrication, calibration, and storage, you can prevent premature wear and tear on the Oxygen regulator components. Proper handling and transportation practices also contribute to preserving its functionality over time.

Additionally, staying vigilant with routine inspections allows you to identify any potential issues early on before they escalate into major problems. Addressing minor concerns promptly can help avoid costly repairs or replacements down the line.

Investing time in training and education on how to properly use and maintain your regulator can significantly impact its longevity. By understanding best practices and following guidelines diligently, you are actively contributing to extending its lifespan for continued reliability when you need it most.

Conclusion:

Ensuring the proper maintenance and care of your oxygen regulator is crucial for its functionality and longevity. By familiarizing yourself with the components, safety precautions, cleaning procedures, and calibration guidelines, you can optimize the performance of your equipment. Regular inspections, lubrication techniques, storage practices, and handling protocols also play a vital role in keeping your regulator in top condition.

In addition to following manufacturer recommendations and staying compliant with regulations, it’s essential to stay prepared for emergencies and prioritize training and education on oxygen supply systems. Upgrading or replacing outdated Oxygen regulator when necessary is key to adapting to changing needs. Consider environmental factors that may impact the efficiency of your regulator and take proactive measures to mitigate risks.

By taking responsibility for maintaining your regulator properly, you not only extend its lifespan but also ensure a reliable source of oxygen when needed most.